The hydrocyclone, made of polyurethane, has the advantages of high wear resistance, high strength, high elasticity, light weight, corrosion resistance, aging resistance, and convenient maintenance and management. In recent years, it has been widely used in oil mining and non-ferrous metals. In metal and non-metallic ores, it can be a good partner of the mill as part of the classification system; in gravity separation, it can take on the heavy task of desludging; in sand washing, it can be a dewatering device; in tailings treatment, it can concentrate the tailings so that it can be sent to the underground mining tunnel for filling.

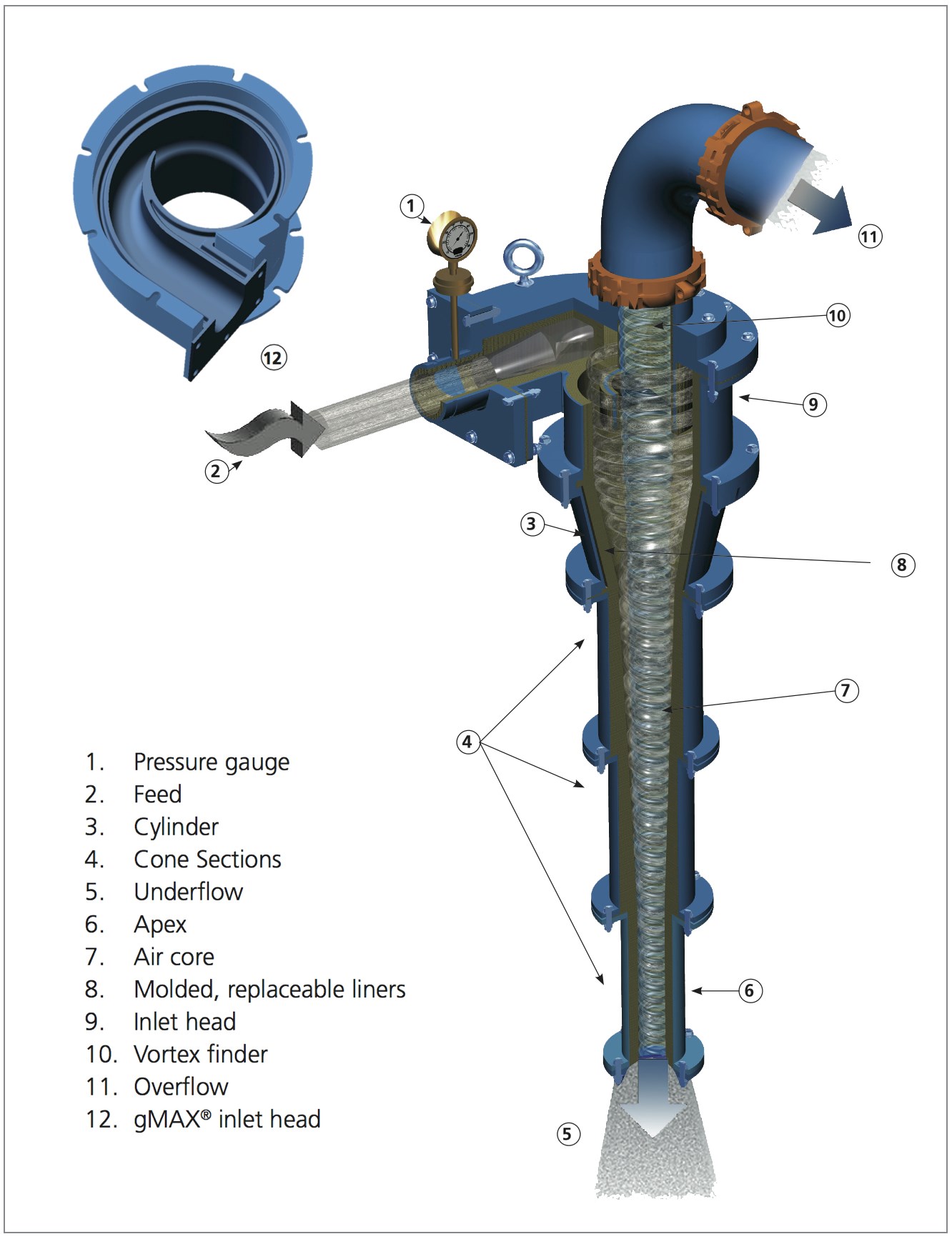

The hydrocyclone is a conical container with a cylindrical structure. The conical part of the upper cone is called the liquid cavity. There is a liquid inlet pipe on the outside of the cone cell, which is connected to the liquid cavity in a tangential manner. The top of the container is the overflow port, and the bottom is the bottom flow port (also called the discharge port). A hollow circular tube can extend from the top to the liquid cavity along the axis of the traditional cyclone separator. This circular tube is called an overflow tube, also known as an eddy current detector. An overflow channel is formed inside it so that the mud overflows and is discharged. The size of the cyclone separation depends on the inner diameter of the cone. Under the action of the mud cyclone, a low-pressure area is developed in the middle of the cone, forming an air column, which causes the impact vacuum and vacuum extraction. The light mud is discharged from the upper opening, and the heavy particles are thrown onto the barrel wall, slide along the barrel wall, and are discharged from the lower opening.

The main column cone of the hydrocyclone is designed with multiple angles, and the column cone length and the overflow adapter are inserted into a reasonable depth ratio, which effectively improves the grading management efficiency of the hydrocyclone. Therefore, in some applications, a large number of small cyclone separators are used to meet the separation requirements, and now only a small number of large cyclone separators can achieve the same effect.

https://www.tufflexscreen.com/hydrocyclone.html

can not be empty

can not be empty