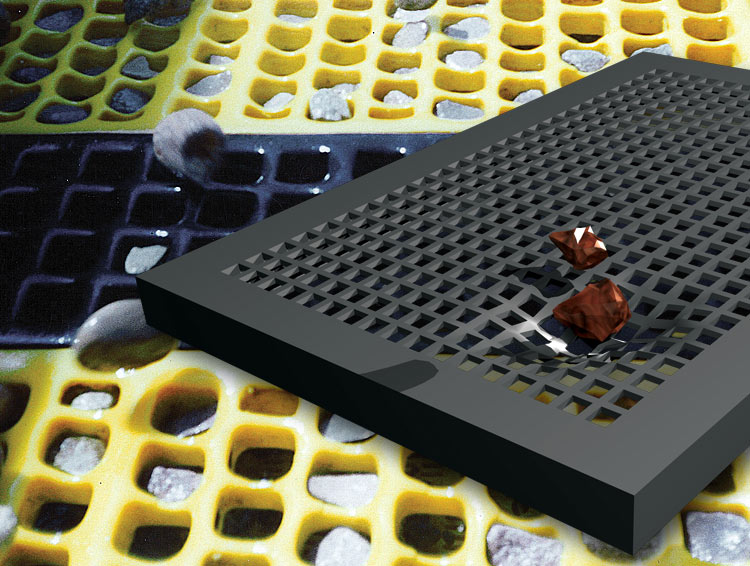

In the mineral processing and aggregate sectors, the initial screening phase stands as the “frontline defense” of the entire operation. This is where unprocessed run-of-mine material—complete with large, uncrushed rocks and ore—first enters the processing loop. It’s also the most demanding and cost-heavy stage: the massive impact force and extreme abrasion from falling bulk material put intense stress on screening media. Conventional steel screen panels often succumb quickly to this punishment, suffering deformation, cracking, and accelerated wear. Worse, the harsh metal-on-metal collisions produce excessive noise, creating an unsafe work environment. Metal fatigue can even lead to sudden failure, sending dangerous debris flying. For operations, this means a relentless cycle of unplanned downtime for screen replacements—each stoppage brings not just spare part costs, but also crippling production losses and reduced overall equipment effectiveness (OEE), eating into profitability.

But what if there was a screening solution that didn’t just survive this harsh environment, but excelled in it? At HUATAO GROUP, our engineered rubber screen panels are designed to do precisely that: transforming your most costly screening bottleneck into a pillar of efficiency and reliability.

Steel’s inherent rigidity is its downfall in tough screening tasks:

Our rubber screens aren’t just a substitute for steel—they’re a complete redesign focused on long-term durability:

We don’t just manufacture rubber panels—we engineer them for peak performance, with key features that set us apart:

A granite quarry previously replaced steel scalping panels every 4–6 weeks. After switching to HUATAO rubber panels, their replacement cycle extended to over 8 months. This single change reduced their annual screening media costs by more than 60% and eliminated the unplanned downtime that had long disrupted production.

In heavy-duty screening, the goal isn’t to find cheaper screens to replace often—it’s to find a smarter solution that needs replacement far less. HUATAO rubber screen panels are that solution: a high-value investment that delivers clear ROI through unmatched durability and consistent operation.

Ready to end the cycle of frequent screen changes?

Follow HUATAO GROUP for more insights into heavy-duty mining and quarrying solutions.

HUATAO GROUP – Your Partner in Durable and Efficient Screening Solutions.

Annie Lu | Huatao Group

Polyurethane Fine Screen Panels | Tufflex Screens | Shale Shaker Screens

HUATAO Group – Your Trusted Supplier for High-Performance Screening Solutions.

can not be empty

can not be empty