In mineral processing, vibrating screens are subjected to extreme conditions—constant vibration, heavy loads, and abrasive materials. Despite being a fundamental stage in production, screening systems frequently encounter technical difficulties that undermine overall plant performance and inflate operational expenses.

Drawing from global mining feedback, this article details seven widespread challenges and offers insights into their origins and mitigation strategies.

One frequently reported issue involves screen panels becoming loose or misaligned during operation. Primary causes encompass inconsistent clamping pressure, deformation of deck supports, and design mismatches between panels and fixation systems. Such instability not only hampers separation accuracy but also induces accelerated wear on adjacent components.

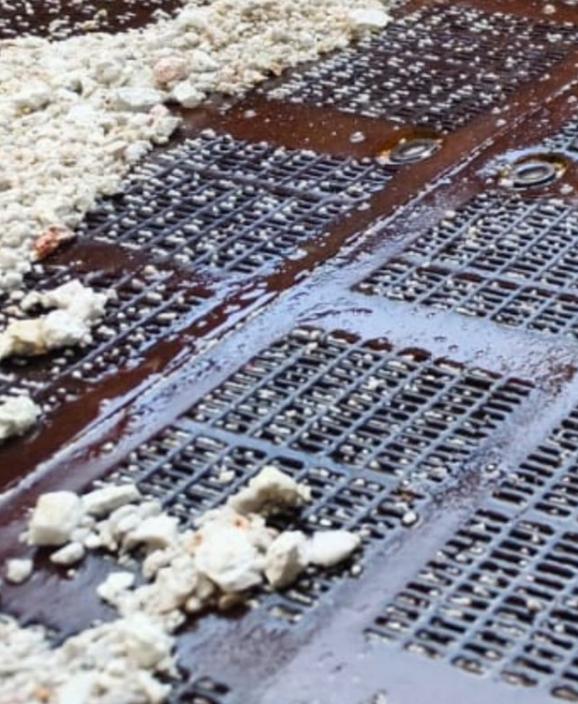

In applications involving highly abrasive ores, screening media often exhibit shortened service life. Contributors include inappropriate wear-resistant material selection, excessive operational G-forces, and non-uniform material spread across the deck. Abnormal wear traces usually signal deeper operational or mechanical irregularities.

Processing moist, adhesive, or finely ground materials regularly leads to blinding—where particles lodge in screen openings. This diminishes active screening area, curtails throughput, and prompts operators to raise vibration intensity, which in turn escalates mechanical wear and energy consumption.

Declining screening precision, manifested as misplaced particles in oversize or undersize streams, disrupts subsequent processing stages. This often stems from ill-suited aperture dimensions, diminished open area due to clogging or wear, and media profiles not optimized for the intended cut point.

Progressive increases in operational noise and vibration transmission are common, especially in older installations. Typical sources include degraded isolation springs, rigid screening media that transmit vibration directly, and structural fatigue in screen assemblies, collectively affecting both machine health and working environment.

Bearing-related failures are predominant causes of unexpected production stoppages. Contributing factors involve sustained high-load functioning, inadequate lubrication protocols, and absence of predictive monitoring systems, allowing minor issues to escalate into major breakdowns.

For dewatering duties, a noticeable rise in product moisture content over time often correlates with worn screen surfaces, incorrect deck angles, or declining vibratory efficiency, posing challenges for downstream handling and product specifications.

The recurrence of these operational issues typically points to systemic discrepancies rather than isolated part failures. A holistic approach—encompassing correct screen media specification, appropriate machine setup, and consistent condition assessment—is vital to enhancing reliability, sustaining throughput, and controlling long-term operational expenditures.

For expert guidance on screening optimization or media selection, reach out to our team:

Annie Lu | Huatao Group

Email: annie.lu@huataogroup.com

Phone/WhatsApp: 008618032422676

#VibratingScreen #MiningScreening #ScreeningMedia #MineralProcessing #OperationalChallenges #Downtime #BearingFailure #Blinding #ScreenWear #NoiseControl #Dewatering #Maintenance #MiningEquipment #ProcessingEfficiency #CostReduction #IndustrialScreening #HuataoGroup #MiningSolutions #Engineering #ProductionOptimization

can not be empty

can not be empty