2026-01-12 Polyurethane Screen Panels Are Transforming Industrial Screening Performance Worldwide

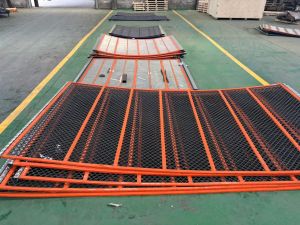

Polyurethane Screen Panels Set New Standards for Industrial Screening Efficiency As global mining and industrial operations pursue higher output with lower operating cost, the limitations of conventional steel screening systems have become increasingly evident. Frequent replacements, corrosion da...

WhatsApp

WhatsApp