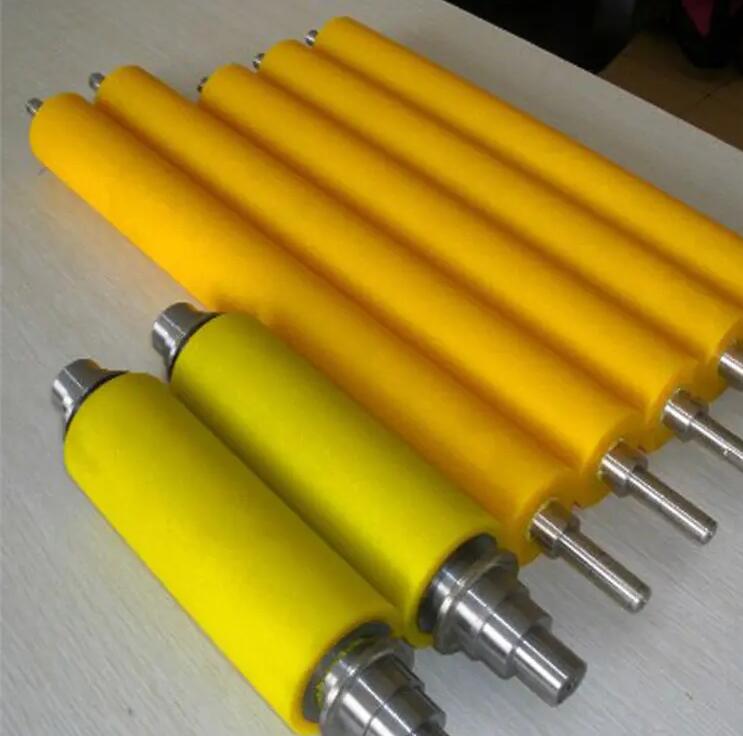

Polyurethane Covered Rollers are a versatile and essential component in various industries, offering a wide range of applications and benefits. These rolls are coated with a durable polyurethane material, providing exceptional resistance to abrasion, chemicals, and wear. The combination of the polyurethane covering and the roll's core material creates a reliable and long-lasting solution for many industrial processes.

One of the key advantages of polyurethane covering rolls is their ability to withstand harsh operating conditions. Whether it's in the manufacturing, printing, or material handling industry, these rolls can endure heavy loads, high speeds, and continuous use without compromising their performance. This durability makes them an ideal choice for applications that demand reliability and longevity.

Polyurethane coated rollers have become a common and essential component in various industries due to their unique characteristics, advantages and wide range of applications. These rollers are known for their durability, wear resistance and ability to withstand harsh working conditions. Let’s take a detailed look at the characteristics, advantages and applications of polyurethane coated rollers.

Feature:

Polyurethane covered rollers are designed to provide superior performance in demanding environments. They are known for their high load-bearing capacity, excellent wear resistance and low coefficient of friction. These rollers are also resistant to chemicals, oils and solvents, making them suitable for a wide range of applications.

Advantage:

One of the main advantages of polyurethane coated rollers is their long service life. They last longer than other types of rollers, reducing the need for frequent replacement and maintenance. Additionally, these rollers offer excellent grip and traction, making them ideal for applications requiring precise movement and control. Their ability to dampen vibrations and reduce noise levels further increases their appeal in industrial settings.

Application:

Polyurethane covered rollers are used in a variety of industries, including material handling, printing, packaging and food processing. In material handling, these rollers are used in conveyor systems to facilitate the movement of goods and materials. In the printing industry, they are used in printing presses to achieve smooth and consistent paper feeding. In addition, polyurethane covered rollers are used in packaging machinery for tasks such as guiding, tensioning and conveying. Their resistance to moisture and chemicals also makes them suitable for use in food processing equipment.

In summary, polyurethane covered drums are a versatile solution for industries that require durable, high-performance components. Their unique features, benefits and wide range of applications make them an indispensable asset in a variety of manufacturing and processing operations. Whether used to transport heavy loads, ensure printing accuracy or maintain hygiene in food processing, polyurethane-coated rollers continue to prove their worth in a variety of industrial environments.

can not be empty

The E-mail format is not correct

can not be empty