In the mining and aggregate sector, picking the right screen panel is a make-or-break decision for optimizing operational efficiency, cutting downtime, and controlling costs. As a trusted provider of high-performance screening solutions, HUATAO GROUP brings you a comprehensive comparison of three mainstream screen panel types—steel, polyurethane, and rubber. We dive into their material properties, open area rates, screening efficiency, anti-blinding capabilities, and durability, backed by real-world application cases. Whether you’re dealing with wet, sticky, or large-sized materials, this guide will help you make an informed choice to elevate your screening process.

As a leading manufacturer of mining screening solutions, HUATAO GROUP specializes in producing high-performance polyurethane screens and rubber screen panels for precise mineral separation. To help you optimize efficiency, reduce downtime, and lower overall operating costs, we break down the key differences between steel, polyurethane, and rubber screen panels below:

Open area is a critical metric for screening efficiency, as it directly impacts material throughput. Here’s how the three types compare:

These factors determine how well a screen panel performs in real-world mining scenarios, especially when dealing with tricky materials:

HUATAO GROUP’s solutions have been put to the test in global mining operations, delivering tangible results:

A customer in Australia struggled with severe blinding issues on their steel and polyurethane screens, worsened by frequent wet weather. We supplied them with 40 Shore A rubber screen panels. After three months of use, the panels showed almost zero blinding, significantly boosting screening efficiency and reducing maintenance time.

For a molybdenum ore screening project, we installed a mixed setup on a banana screen: 60 Shore A rubber panels at the feed end (to handle heavy initial impact) and 40 Shore A rubber panels at the discharge end (to enhance anti-blinding for finer particles). The result? No blinding, minimal wear, and high customer satisfaction with both performance and longevity.

We actively participate in international mining and aggregate exhibitions, welcoming strategic visits from global brands. Our focus is on delivering customized screening solutions tailored to the unique needs of operations worldwide—whether you need panels for wet, dry, abrasive, or sticky materials.

When evaluating screening efficiency, anti-blinding performance, and longevity, rubber screen panels stand out as the superior choice—especially for operations dealing with wet, sticky, or large-sized materials. Steel and polyurethane panels have their merits (steel for high open area in dry, non-sticky scenarios; polyurethane for abrasion resistance), but rubber offers the best balance of reliability and performance for most challenging mining environments.

Annie Lu | Huatao Group

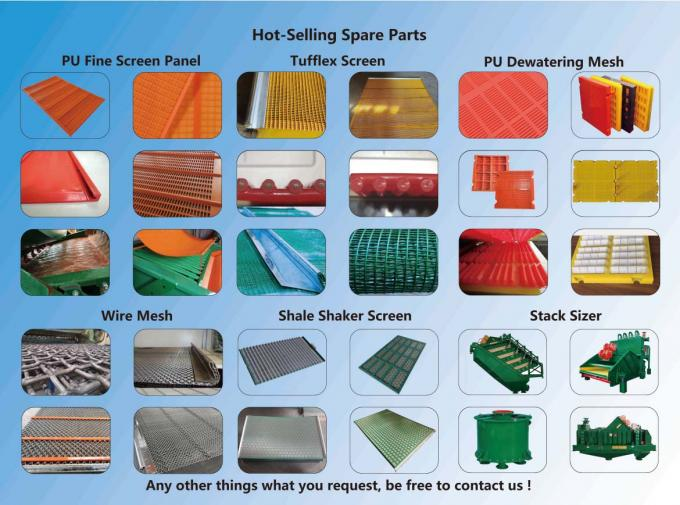

Polyurethane Fine Screen Panels | Tufflex Screens | Shale Shaker Screens

HUATAO Group – Your Trusted Supplier for High-Performance Screening Solutions.

can not be empty

can not be empty