Rubber filter plates are usually made of high-quality rubber materials, consisting of rubber diaphragms and supporting structures, lt forms a sealed diaphragm during the filtration process separating the filtering medium from the filtrate and preventing the filtrate from passing through the diaphragm. The supporting structure is made of metal or plastic and is used to fix and support the rubber diaphragm, allowing the filtrate to pass through and enter the filtering medium.

Description:

Rubber filter plates are usually made of high-quality rubber materials, consisting of rubber diaphragms and supporting structures, lt forms a sealed diaphragm during the filtration process separating the filtering medium from the filtrate and preventing the filtrate from passing through the diaphragm. The supporting structure is made of metal or plastic and is used to fix and support the rubber diaphragm, allowing the filtrate to pass through and enter the filtering medium.

The sealing performance of rubber filter plates is excellent, with good corrosion resistance, wear resistance, and high temperature resistance. it can adapt to various media and environments, and can affectively achieve higher filtration efficiency and cake dehydration through the compression and expansion of the diaphragm, Rubber filter plates are widely used in liquid filtration and separation processes in industries such as chemical, pharmaceutical, food, and beverage.

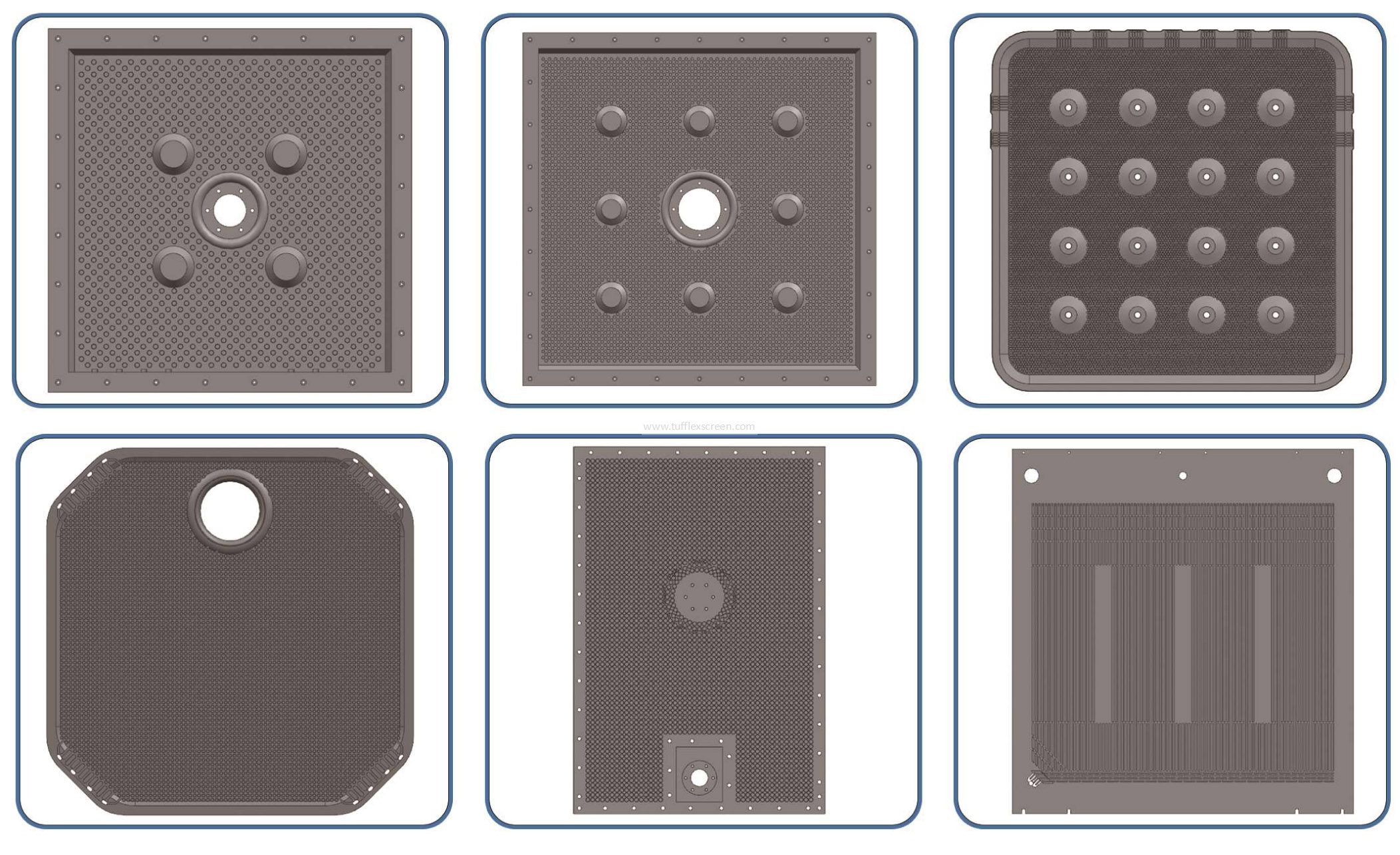

Composite rubber diaphragm filter plate:

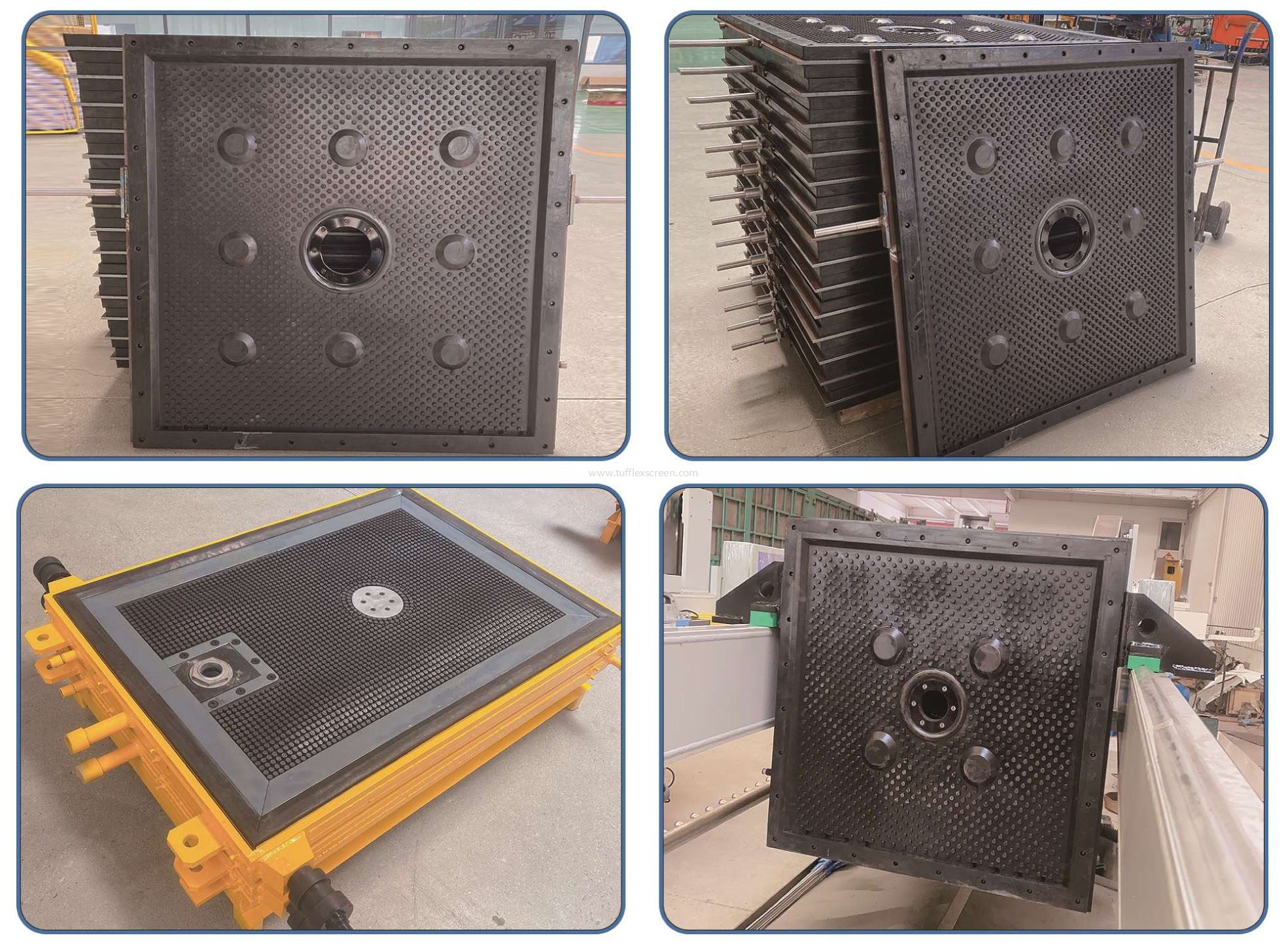

Whole Machine assembly plate and frame filter press

The selection of rubber filter plates suitable for specific applications requires consideration of the following factors:

1. Filtrate properties: understanding the chemical properties, temperature, pH, and other factors of the filtrate, and selecting rubber materials that can withstand these conditions.

2. Filtration requirements: determining the required filtration accuracy, flux, and dehydration effect, and selecting rubber diaphragm filter plates with corresponding performance.

3. Work pressure: Consider the working pressure of the filtering equipment to ensure that the rubber diaphragm filter plate can withstand the corresponding pressure requirements.

4. Wear resistance and corrosion resistance: Select a rubber diaphragm filter plate with sufficient wear and corrosion resistance based on the degree of wear and corrosion in the application environment

5. Size and installation requirements: Ensure that the size and installation method of therubber diaphragm filter plate are compatible with existing equipment.

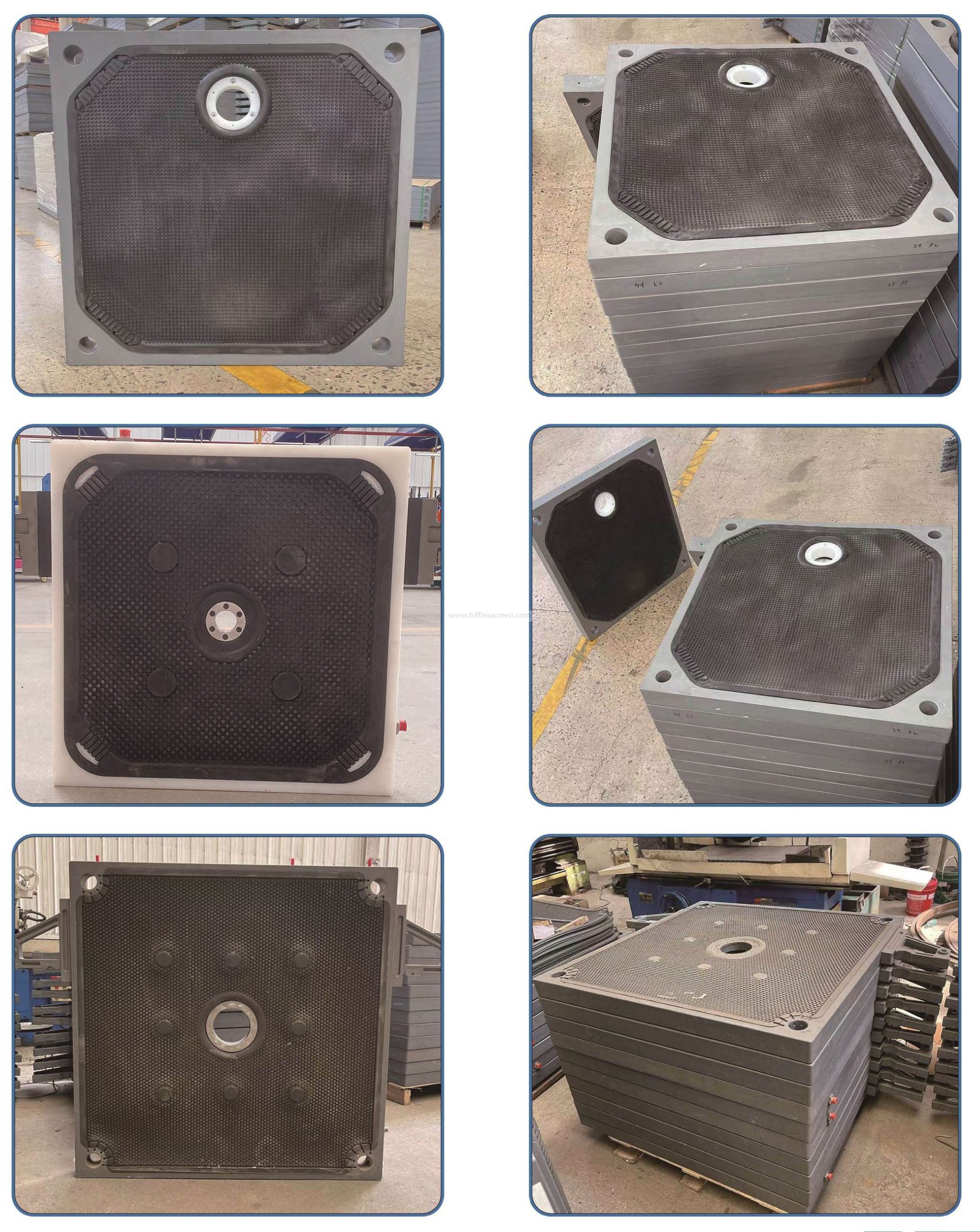

Actual photo of rubber diaphragm filter plate:

Contact us ↓

Annie Lu

Huatao Group

annie.lu@huataogroup.com

Mobile: 0086 18032422676 ( Whatsapp/Wechat/Viber)

can not be empty

The E-mail format is not correct

can not be empty