Description Of Ceramic Lined Cyclone

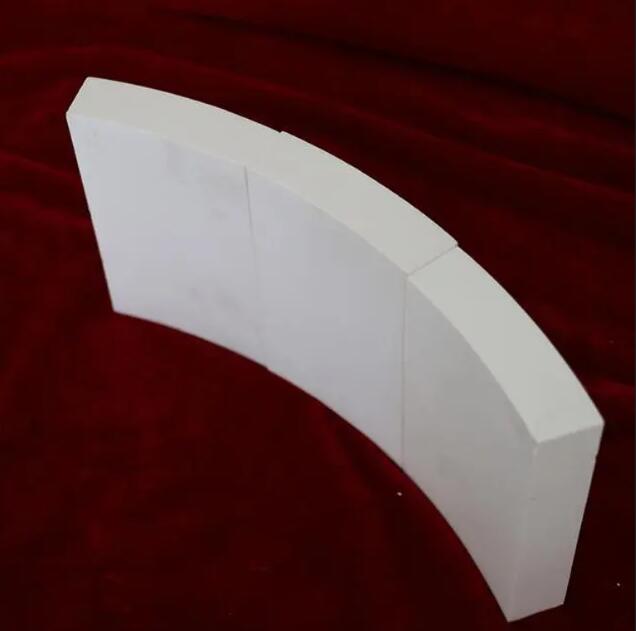

In industrial production, cyclones are widely used in mining, chemical environmental protection, food processing and other fields as an efficient and economical separation equipment. Its core function is to achieve effective separation of liquid and solid particles through the action of rotating flow field. However, due to the high-speed rotation inside the cyclone and the frequent collisions between particles, the inner wall and key components are often under tremendous wear pressure, especially when dealing with high-hardness or highly abrasive materials. Therefore, the installation of cyclone ceramic lining has become an important link to extend the service life of the cyclone and ensure separation efficiency.

wear resistance was improved Significantly : Alumina ceramic as the wear-resistant lining material. Its extremely high hardness ensures that the cyclone can effectively resist material erosion and friction during high-speed rotation, greatly extending the service life of the Cyclone. This not only reduces production interruptions caused by frequent parts replacement, but also reduces maintenance costs and replacement material expenses, improving overall operational efficiency.

Guarantee material purity&Improve material selection quality: The wear-resistant ceramic anti-wear layer is almost wear-free, which prevents the wear debris generated by the wear of traditional materials from mixing into the material, thereby ensuring the purity of the material. wear-resistant ceramic lined cyclones can more accurately achieve material classification and concentration, thereby improving the quality of the final product. This is especially important for industrial applications that require high-precision separation, such as mineral processing and chemical industry, which can directly improve the market value of the product and customer satisfaction.

Optimize fluid dynamics: The inner wall of the wear-resistant ceramic-lined cyclone is extremely smooth, the height difference between the ceramic sheets is extremely tiny. This design helps to reduce the turbulence and resistance of the fluid in the cyclone, making the material flow smoother and maintaining a higher tangential velocity. This not only reduces energy loss, but also improves classification efficiency and concentration effect, making the separation process more precise and efficient.

Enhance equipment stability and reliability: Due to the high strength and durability of wear-resistant ceramic materials, the cyclone can maintain a stable operating state even under harsh working conditions, reducing downtime and production losses caused by equipment failure. This high degree of stability and reliability is an indispensable and important factor in modern industrial production.

can not be empty

The E-mail format is not correct

can not be empty