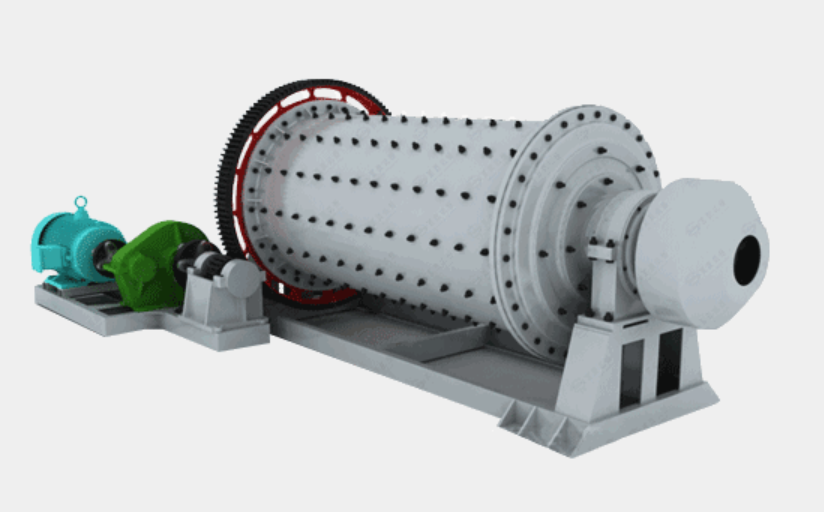

The diameter of the ore shaft at the discharge end of the overflow type ball mill is larger than the diameter of the hollow journal at the feed end, resulting in a height difference between the pulp surface of the feed end and the discharge end in the mill, which promotes the automatic overflow of the pulp from the discharge end. The overflow type ball mill is a new type of ball mill equipment with simple structure and self-flow discharge of ore. It is often used to grind fine ores. If multi-stage grinding is used, it is generally used in two-stage and three-stage grinding. Its cylinder body uses a high wear-resistant lining plate, which has the characteristics of good wear resistance, long service life and convenient maintenance.

Processing material

Molybdenum, iron, lead, manganese, tungsten, cement, ceramics, barite, bauxite, limestone and other ferrous and non-ferrous materials.

Scope of application

Widely used in beneficiation, building materials, chemical industry, ore industry, ferrous and non-ferrous metal beneficiation and glass ceramics and other production industries.

Features

1. Equipped with a jack-up device, which is convenient for maintenance, and can be used for dry or wet grinding with high efficiency;

2. The barrel of the overflow ball mill is inlaid with wear-resistant materials, so as to enhance the wear resistance and prolong the service life;

3. The large and small gears are lubricated by oil mist to ensure reliable lubrication of the large and small gears, prolong the service life of the large and small gears, and save lubricating oil;

4. Equipped with air clutch, flexible start is adopted to reduce the number of ball mills, which will cause a greater impact on the power grid of the dressing plant during start-up;

5. The overflow type ball mill replaces the rolling bearing with the bearing bush sliding bearing, which not only saves energy but also reduces consumption; in addition, the machine is also equipped with an integral large plate, which shortens the installation time and reduces the installation requirements.

Parameter

|

Model

|

Cylinder diameter(mm) |

Cylinder length (mm) |

Type of motor |

Power of motor (KW) |

Motor speed (r/min) |

Outer Size (L*W*H) (mm) |

Available capacity (㎡) |

Maximum ball loading (t) |

Weight (kg) |

capacity (t/h) |

||

|

HT0918 |

900 |

1800 |

Y225M-8 |

22 |

730 |

5080 |

2300 |

2015 |

0.9 |

1.66 |

6078 |

0.37-1.8 |

|

HT1212 |

1200 |

1200 |

Y250M-8 |

30 |

730 |

5023 |

2794 |

2540 |

1.14 |

2.4 |

11473 |

0.2-4.1 |

|

HT1224 |

1200 |

2400 |

YR280S-8 |

55 |

723 |

6112 |

2794 |

2540 |

2.28 |

3.8 |

12308 |

0.35-8.2 |

|

HT1515 |

1500 |

1500 |

JR115-8 |

60 |

723 |

5766 |

2945 |

2600 |

2.2 |

6.4 |

15424 |

1.4-5 |

|

HT1530 |

1500 |

3000 |

JR125-8 |

95 |

725 |

7979 |

2945 |

2600 |

4.5 |

10 |

18690 |

2.5-8 |

|

HT2122 |

2100 |

2200 |

JR128-8 |

155 |

730 |

8070 |

4840 |

3795 |

6.6 |

14 |

47600 |

4.5-26 |

|

HT2130 |

2100 |

3000 |

JR137-8 |

210 |

735 |

8870 |

4840 |

3795 |

9 |

20 |

49780 |

4-30 |

|

HT2136 |

2100 |

3600 |

JR137-8 |

210 |

735 |

9300 |

4840 |

3795 |

10.8 |

22 |

52010 |

4.8-36 |

|

HT2145 |

2100 |

4500 |

JR148-8 |

310 |

740 |

11029 |

4737 |

3300 |

13.5 |

23.8 |

58305 |

8-35 |

|

HT2430 |

2400 |

3000 |

JR1410-8 |

280 |

740 |

9710 |

4778 |

4120 |

12.1 |

23 |

65880 |

6.2-77.6 |

|

HT2721 |

2700 |

2100 |

JR1410-8 |

280 |

740 |

9400 |

5600 |

4700 |

10.7 |

24 |

63900 |

7-78 |

|

HT2736 |

2700 |

3600 |

TDMK400-32 |

400 |

187.5 |

11400 |

5700 |

4500 |

18.4 |

38 |

70000 |

10.5-130 |

|

HT2740 |

2700 |

4000 |

TDMK400-32 |

400 |

187.5 |

11850 |

5667 |

4496 |

20.4 |

40 |

78800 |

12-145 |

|

HT3231 |

3200 |

3100 |

TDMK630-36 |

630 |

167 |

12750 |

6760 |

5150 |

21.4 |

45 |

107660 |

74-86 |

|

HT3245 |

3200 |

4500 |

TDMK630-36 |

630 |

167 |

14600 |

6760 |

5200 |

31 |

61 |

112000 |

86-100 |

|

HT3254 |

3200 |

5400 |

TM1000-36/2600 |

1000 |

167 |

15600 |

6760 |

5200 |

37.2 |

73 |

121000 |

112-135 |

|

HT3645 |

3600 |

4500 |

TM1000-36/2600 |

1000 |

167 |

15000 |

7200 |

6326 |

41.8 |

76 |

135000 |

170 |

|

HT3650 |

3600 |

5000 |

TM11250-40/3250 |

1250 |

150 |

17157 |

7755 |

6326 |

46.4 |

86 |

145000 |

40-178 |

|

HT3660 |

3600 |

6000 |

TM11250-40/3250 |

1250 |

150 |

19000 |

7755 |

6326 |

55.7 |

102 |

154000 |

186 |

can not be empty

The E-mail format is not correct

can not be empty